-

- The global specialized manufacturer of liquid level gauges for industrial use. We have the top share of the market for glass type liquid level gauges.

- The first in Japan to develop and commercialize magnet float type liquid level gauges. These gauges are used in petrochemical plants in various countries around the world.

- We manufacture and sell glass type liquid level gauges (direct viewing), magnet float type liquid level gauges, and sight glass.

- The products cover a range of uses according to the process, from high temperatures and high pressure to extremely low temperatures, and to general-purpose products.

- We maintain relationships with our customers through after-sale maintenance services, search for customer needs, and establish firm relationships of mutual trust.

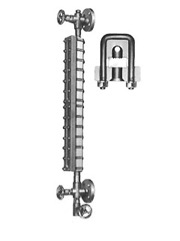

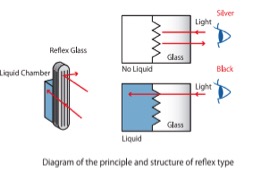

Reflex Type.

- PRINCIPLE Prismatic serrations of the whole visual area on the liquid contact surface of reflex glass gives a prism effect.

- The reflex prisms are moulded and polished to provide a crisp black silver bi-color indication of the fluid level.

- When light passes into reflex glass, if there is fluid present the light continues through the glass an impact the back of the level gage, provided a black color for fluid level regardless of the actual color properties of the process fluid.

- If fluid is not present, the light is reflected back towards the user providing a shiny silver.

- Reflex types are not suitable for alkaline liquid because mica plate cannot be attached on the surface of prismatic serrations. *NIHON KLINGAGE has developed Alkaline resistant glass named LUKING-AR referring to Glass Products page.

Feature

- Less expensive than Transparent Type

- Lower cost of maintenance than Transparent Type

- Easier to observe the level of clear liquid than Transperent Type

- Various material choices : Carbon steel (S25C、A105), stainless steel (SUS304、SUS316、SUS304L、SUS316L), Titanium, Monel, Hastelloy and various resin linings

- Various options: Ultraviolet cut plate, Light-shielding chamber, Thermal jacket, Non- frosting window for the low temperature and Large diameter chamber for high viscosity fluid and Scales

- Installation support is available.

- NIHON KLINGAGE is ready to design Reflex Type Level Gages according to customer’s requirement

Transparent Type.

- PRINCIPLE Flat tempered glass is mounted on each side of the liquid chamber and held between gage covers.

- Liquid level, boundary level and liquid color are observed by the differece of transmission of light emitted from the illuminator behind.

Feature

- Applicable for almost all liquid including Alkaline solution

- Suitable to observe boundary surface

- Suitable to observe the color of the liquid

- Various material choices : Carbon steel (S25C、A105), stainless steel (SUS304、SUS316、SUS304L、SUS316L), Titanium, Monel, Hastelloy and various resin linings

- Various options : Ultraviolet cut plate, Light-shielding chamber, Thermal jacket, Non- frosting window for the low temperature liquid, Large diameter chamber for high viscosity fluid, illuminators ( Explosion-proof ) and Scales

- Installation support is available.

- NIHON KLINGAGE is ready to design Transperent Type Level Gages according to customer’s requirement.

Tubular Type

- Tubular glass or resin forms a liquid chamber between upper and lower gage valves. It is the most simple and inexpensive liquid level gage which can be used under normal or relatively low pressures.

- Tube can be marked with red lines to observe the liquid level easily. Resin(Fluorocarbon, Acrylic and PVC) tubes can be used for corrosive liquid.

Scale board, float (applicable for the liquid of specific gravity over 0.55) and jacket are available. - As for valve material, carbon steel, stainless steel (SUS304,SUS304L,SUS316,SUS316L) , resin (PP,PVC) and several lining are available.

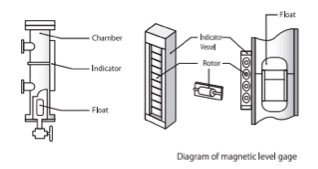

Magnetic Type

INTRODUCTION

Since 1955, NIHON KLINGAGE has been making magnetic level gages in Japan and providing to the world.

Our Magnetic Level Gauge provides safe, reliable and maintenance free solution to liquid level detection of toxic, corrosive, high pressure, high temperature

FEATURE

3 main components

- Float chamber: The chamber is made of non-magnetic material and is attached on vessel. A float is housed in the non-magnetic float chamber. The float will move up and down in the chamber as level rises or falls in the vessel on which it is attached.

- Magnetic float: Floats are individually designed and optimized for each application according to working condition.

- External indicator: The hermetically sealed indicator unit, which is mounted on the outside of the gage, contains a magnetic indicator that interlocks magnetically with the float inside the chamber. As the float moves up and down with the liquid level, the magnetic indicator element tracks the changes in level.

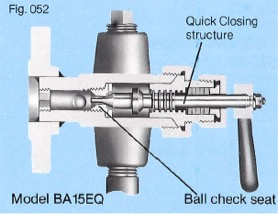

Check Ball Valves.

- The NKG Check ball valve will operate in the presence of huge pressure surge from the vessel.

- In the event of emergency blow out due to glass break the valve will be automatically shut by the ball.

- When the check ball is operated, the leakage or loss of containment can be reduce to 0.3l/min or less (as per NKG Standard)

- It is a standard fitting for gage valves approved by High Pressure Gas Regulation Law (Japan)

Luking AR Glass

Glass has excellent corrosion resistance in general but is attacked and dissolved in service by alkaline solution, resulting in thinning of the wall and premature failure or replacement. High alkalinity and high temperature increase the rate of attack.

LUKING-AR has excellent resistance to high alkalinity and high temperature which enables reflex type gage is adoptable to high pressure boiler applications.

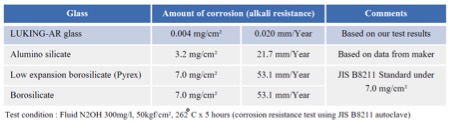

Alkaline Resistance

LUKING-AR is 800 times stronger than alumino-silicate glass and 1,750 times than borosilicate glass.

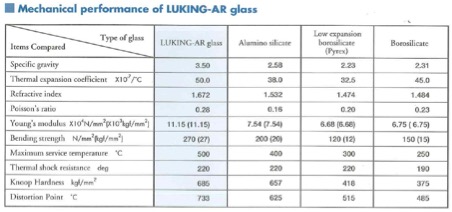

Mechanical strength

Bending strength: 270N/mm2(27kgf/mm2).

Temperature resistance

Maximum service temperature: 500℃.

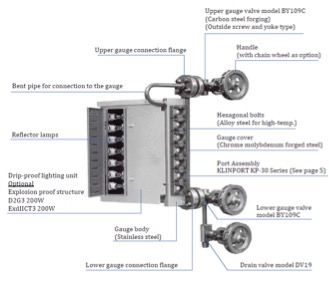

BN200 High Pressure

BN200 series is Bi-Color boiler water level gauge were design mainly purpose for super high pressure drum boiler meet ASME Section I-POWER BOILER regulations with high quality of material and safety design.

BN200 Bi-Color water level gauge can meet at max.pressure 220kgf/cm2 (216 barG), and max. temperature 372ºC.

This type of Level Gauge usually either using Klinport + mica or Klinport + Luking AR as the glass.

Develop for use with the BN200 Series Level gauge, Klinport “KP-30” series is a product with a high level of safety featuring high strength(pressure) and heat resistance(temperature).

The Klinport “KP-30” series is a composite unit comprising a special metal ring fused to highly heat resistance glass.

This is a highly innovative product which fully utilizes the advantages of the properties of the materials comprising Klinport.

Feature

- Configuration

- The glass is fused to a tempered metal ring and to avoid damage to the mica, the seal faces are polished to a smooth finish.

- Pressure and Heat resistance

- The glass is fused to the ring in a tempered form which gives especially good pressure resistance. The expansion coefficient of the metal frame and the glass have been made similar.

- Shock Impact properties

- The metal frame and glass form a single integral body thus made the has an ample strength and feature with outstanding vibration & shock impact properties.

- Safety

- Even if the glass cracks, as it firmly pressed in by the metal frame there would be not affected the strength of the glass and the glass splinter would not fly out. Thus, Klinport ensures a high level of safety.

No products were found matching your selection.